Key Insights

As urban centres expand and transport networks become more complex, tunnels and other transport infrastructure are at the forefront of both engineering ambition and safety obligation. One of the most critical safety challenges in these enclosed, high-risk spaces is fire: controlling its impact, protecting life and assets, and ensuring infrastructure resilience.

In this post, we explore how modern fire protection standards are evolving in the Tunnel and Transport Infrastructure transport sector and how Progressive Materials (as an authorised distributor of Promat passive fire protection solutions) is uniquely placed to support best-practice outcomes.

The fire risk landscape in tunnels and transport infrastructure

Tunnels, underground passages, and related transport structures present a unique fire safety environment. Some of the key challenges include:

- Confined space effects

Fires in tunnels can produce rapidly developing heat, smoke, toxic gases, and high pressure from expansion of gases. Without adequate protection and compartmentation, the effects can propagate quickly along the tunnel. - Structural vulnerability

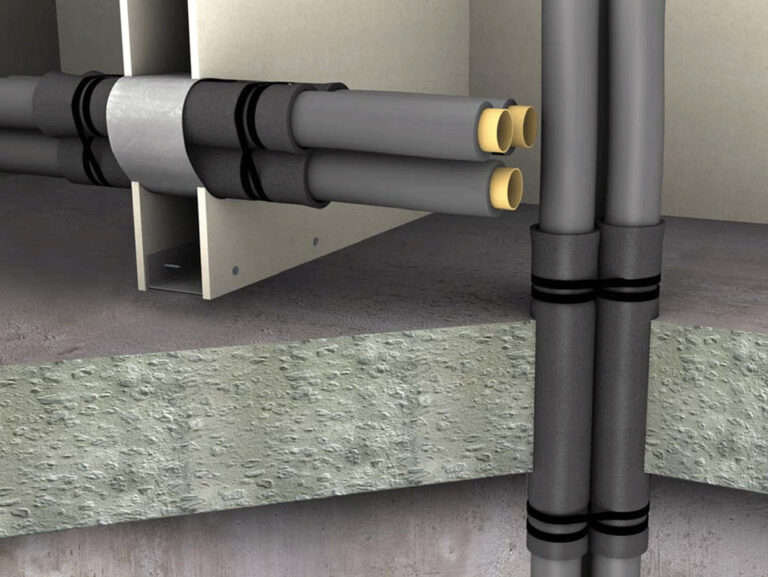

Tunnel linings, steel supports, concrete structures, and service penetrations may be exposed to elevated temperatures, which can degrade integrity, lead to spalling, or cause structural failure. - Complex services and penetrations

Tunnels require extensive mechanical, electrical, ventilation, drainage, signalling, and other systems. Each penetration (pipes, cables, conduits, ducts) poses a weak point if not properly fire sealed or protected. - Smoke control and egress

Effective ventilation is critical to remove smoke and maintain tenable conditions for evacuation and firefighting. Fire resistance and compartmentation must integrate with ventilation and smoke extraction systems.

Because of these challenges, modern fire protection in tunnels demands passive fire protection (PFP) solutions that can sustain performance under extreme conditions, minimise fire spread, and protect critical structural elements and service penetrations.

Progressive Materials approach to tunnel fire protection

Progressive Materials is partnered with Promat, a global expert in passive fire protection who present a suite of systems tailored to tunnels and transport infrastructure. Their approach encompasses:

- Structural protection of steel, concrete, and timber elements to maintain integrity under fire loads.

- Compartmentation systems, both horizontal and vertical, that limit fire and smoke spread.

- Fire stopping solutions for service penetrations, ensuring that pipe, cable, duct, and conduit openings are sealed without compromising system functionality.

- Ventilation duct protection and smoke extraction system enclosures, integrating passive protection with active safety systems.

Progressive Materials: Bridging specification and delivery in Australia

Progressive Materials is the exclusive distributor in Western Australia for Promat passive fire protection solutions, offering specification support, technical guidance, and local stock for rapid deployment.

Some key value propositions we bring include:

- Full product range availability: From fire rated boards, fire collars, sprays & coatings, to fire stopping systems — we offer the complete Promat line.

- Specification and compliance support: Our team assists design and building teams in aligning to Australian fire safety standards, ensuring correct system selection, testing, and certification.

- Rapid local supply: With local warehousing, our Promat products are available for same-day delivery within WA.

- Project experience: Progressive Materials already participates in transport and civil infrastructure projects (e.g. rail, tunnels) – integrating passive fire systems into large scale built environments.

By combining Promat’s global solutions with our local presence and expertise, we help infrastructure owners, consultants, contractors, and fire safety engineers meet the demanding requirements of tunnel environments.

Aligning with modern fire protection standards

What does “meeting modern fire protection standards” mean in practice for tunnel and transport infrastructure? Some key principles:

- Fire resistance ratings and classification

Structural elements and compartment walls/floors require defined fire resistance periods (e.g. 60, 90, 120, 180 and 240 minutes) in accordance with national and international codes. PFP systems must be rigorously tested and certified. - Fire Curves

There are several types of fire curves, including cellulosic, hydrocarbon, and RWS (Rijkswaterstaat). Each curve simulates a different tunnel fire scenario. In rail and road tunnels, these curves test and certify passive fire protection systems. This ensures systems can handle rapid temperature increases and ongoing heat from vehicle or freight fires. The goal is to align system performance with actual risks.

- Integral system performance, not just products

It’s not enough to pick a fire rated board or coating, the entire assembly (substrate + fixings + joints + transitions + penetrations) must be validated. - Smoke and heat control synergy

Passive fire protection must complement ventilation, smoke extraction, and emergency egress strategies, systems must work in concert. - Durability and maintainability in harsh environments

Tunnel environments may be humid, corrosive (due to exhaust, damp, salts), or subject to vibration and shock. PFP systems must be durable over the long term and accessible for inspection and maintenance. - Sustainability and lifecycle planning

Modern standards increasingly incorporate life-cycle carbon impacts, recyclability, and energy implications of fire protection materials.

By deploying well-engineered PFP solutions, infrastructure projects can not only satisfy regulatory obligations but also enhance resilience, reduce risk, and future-proof systems.

Key recommendations for specifying tunnel fire protection

For project teams and fire safety engineers working on tunnels or transport infrastructure, here are practical recommendations:

- Start early: Engage PFP experts at the design phase to coordinate structural, mechanical, electrical, and fire system integration.

- Adopt tested systems: Rely on certified systems (e.g. from Promat) rather than ad hoc “make your own” assemblies.

- Consider penetrations carefully: For every pipe, cable tray, or duct crossing the fire boundary, specify appropriate fire stopping systems (e.g. Promat’s fire stopping portfolio) to maintain barrier integrity.

- Integrate with ventilation and smoke strategies: Review how passive fire elements impact airflow, smoke extraction, and pressure differentials.

- Plan for inspections and upgrades: Ensure fire protection systems remain serviceable, inspectable, and replaceable where needed.

- Document thoroughly: Maintain as-built records, test certificates, and maintenance plans for future asset management.

Modern tunnel and transport infrastructure demand fire protection solutions that are robust, resilient, and integrated. With the global capability of Promat’s passive fire protection systems and the local expertise and supply chain of Progressive Materials, Australian infrastructure projects can confidently rise to these challenges.

If you’re working on transport or tunnel projects and would like to discuss specification, system selection, or compliance strategies, reach out to Progressive Materials for a tailored consultation.