Key Insights

For architects, designers and commercial-builders seeking facades that combine high performance, aesthetic flexibility and long-term value, fibre cement – especially the premium offering from Equitone – is increasingly the material of choice.

At Progressive Materials, we supply the full Equitone range across Western Australia and partner closely with design-teams to deliver facade solutions that not only meet the brief today but endure for decades.

Here’s why fibre cement outlasts many traditional facade materials and why specifying Equitone through Progressive Materials gives you the best outcome.

What is Fibre Cement — and Why It Matters

Fibre cement is a composite material made from Portland cement, sand (or silica), water and cellulose (or synthetic) fibres. Manufactured under controlled conditions, this results in boards or panels that combine excellent dimensional stability, strength and durability.

Equitone’s fibre-cement panels build on more than 100 years of fibre-cement innovation (via parent company Etex Group) and are purpose-designed for facade applications.

For design‐led facades, this translates into a material that:

- Resists warping, cracking or dimensional change in the face of heat, moisture and climate swings.

- Offers fire resistance, non-combustibility, and high durability.

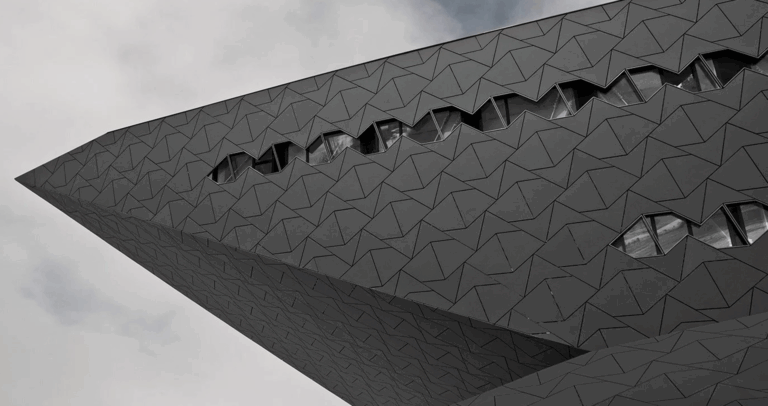

- Gives broad design freedom: large-format panels, cut/milled/perforated shapes, variety of textures and finishes.

Why Fibre Cement Outlasts Traditional Materials

Superior Durability & Weather Resistance

Traditional facade materials such as timber cladding, masonry, or standard metal panels are vulnerable to the elements: moisture ingress, freeze-thaw cycles, UV degradation, pests and corrosion. Equitone premium fibre cement, by contrast:

- Is highly resistant to moisture, rot, rust and decay.

- Performs well in extreme temperature and climate conditions. Fibre cement is used all over the world and across a range of climates thanks to its durability, resilience and safety.

- With Equitone systems, ventilated rainscreen construction helps prevent moisture-laden air being trapped behind the facade, reducing the risk of mould, mildew, structure damage and thermal stress.

Minimal Maintenance & Long Service Life

Facades are long-term assets. The less you intervene, repaint or remediate, the better. Equitone fibre cement panels are designed to last over 50 years with minimal maintenance.

- The panels are through-coloured (i.e., the colour/texture goes through the panel thickness) so minor chips or scratches are less visible and the facade retains its visual integrity longer.

- Non-combustibility and weather performance reduce the risk of early deterioration that might prompt remedial works, saving both time and cost for building owners and facility managers.

- Having a facade provider like Progressive Materials able to supply the full system-components, technical support and stock locally means fewer surprises, more reliability and fewer future headaches.

Fire Performance & Compliance

In many commercial and multi-storey projects, facade fire compliance is a critical specification. Equitone fibre cement panels are non-combustible and engineered for performance in facade systems.

- The metal framing and ventilated rainscreen behind fibre-cement helps manage heat, moisture and structural movement, all of which, over time, contribute to durability and longevity.

- When specifying facade cladding solutions, especially for high-rise or bushfire-prone zones, choosing a material and system with documented fire/rain/ventilation performance helps future-proof the building.

Design Flexibility & Adaptability

Buildings evolve, facades may need to accommodate future works, maintenance, or change in use. Fibre cement panels like Equitone deliver on design flexibility in ways traditional materials struggle:

- Large-format panels that can be cut, milled, perforated, curved or printed maintain their performance characteristics.

- A wide texture and colour palette (raw, sanded, ridged, smooth, bold colours or natural tones) supports the aesthetic ambitions of architects and designers.

- The durability and stability mean design details (overhangs, shapes, cut-outs) are less likely to degrade over time. This means the facade vision you sign off on is the vision the building lives with.

Why EQUITONE and Progressive Materials is the Ideal Specification Route

Selecting a high‐performance facade system is only half the battle. The other half is supply, specification support and local service. That’s where Progressive Materials adds value for architects, facade engineers, contractors and developers:

- Progressive Materials is listed as the supplier for Equitone fibre cement panels in WA, offering local stock, local support and technical consultancy.

- Progressive Materials supplies the full Equitone collection

- Because Progressive Materials focuses on specialist facade, fire protection and architectural linings, they understand the intersection of durability, compliance and design. This is particularly important when facades must meet thermal, acoustic, fire and weather performance criteria.

- Their technical consultants can assist from early specification, through detailing, to installation support, reducing risk of substitution or performance shortfall.

By specifying Equitone panels via Progressive Materials, you are aligning your facade design with:

- A globally reputable material with documented durability and architectural pedigree.

- A local supply chain partner with stock, technical backup and compliance knowledge.

- A facade solution designed not just for today’s look, but for decades of life-cycle performance, low maintenance, strong compliance and reduced total cost of ownership.

Specifier’s Checklist: Ensuring Facade Longevity with Fibre Cement

When procuring a fibre cement facade solution for a commercial or institutional project, consider the following:

- Material specification: Choose high-density fibre cement panels (such as Equitone with through-colour core, documented durability, fire and weather performance.

- System design: Use ventilated rainscreen assemblies that promote airflow behind the panels, reduce heat/moisture build-up and extend facade life.

- Installation quality: Ensure fixings, subframe, joints, penetrations and drainage/ventilation behind the facade are detailed correctly. Even the best material will underperform if installed poorly.

- Maintenance access & life-cycle planning: Specify panels and systems with low maintenance demands, and check how minor damage (chips, scratches) will be addressed.

- Compliance & durability assurance: Confirm the product meets relevant non-combustibility, fire rating and durability standards for your building type and region. Equitone and Progressive Materials both emphasise non-combustible performance.

- Sustainability credentials: For clients seeking green building certification, evaluate environmental credentials. Equitone panels are Cradle to Cradle Certified® Bronze and fully recyclable.

- Local support & warranty: Work with a supplier who offers local stock, post‐sale support, technical documentation and who understands the local climate constraints (e.g., Western Australia’s coastal, high-UV or bushfire conditions). Progressive Materials offers this.

Conclusion

For architects, designers, facade engineers, contractors and building owners looking beyond the near-term to long-term performance, fibre cement facades represent a smart investment. With superior durability, low maintenance, fire and weather resistance, and excellent design flexibility, Equitone premium fibre cement range gives you the confidence that your facade will perform aesthetically, functionally and financially over decades.

By specifying Equitone through Progressive Materials, you bring together a premium facade material and a dedicated supplier partner who understand both the design ambition and the technical realities of WA commercial construction. The result: a facade that looks great today and still looks and performs great many years from now.